Project Summary

Understanding the Impact of Reduced Water Use Beef Spray Chilling System on Beef Carcass Quality and Saleable Yield

- Principle Investigator(s):

- Nick C. Hardcastle, Jerrad F. Legako, J. Chance Brooks, Mark F. Miller, and Dale R. Woerner

- Institution(s):

- Department of Animal and Food Sciences, Texas Tech University

- Completion Date:

- September 2020

Background

The US beef industry utilizes great quantities of water to produce a single kilogram of beef (Rotz et al., 2019). Though the majority of the water is consumed pre-harvesting (Asem-Hiablie et al., 2019), recent reports indicated it requires in excess of 3,000 L of water to process a single animal (Li et al., 2018). Water security in the southern High Plains, a major beef producing area, is becoming a major concern due to the diminishing High Plains Ogallala Aquifer (USGS, 2017). This has required beef processors in this area to begin seeking strategies that conserve water and generate long-term sustainability of their facility. Spray chilling, a process that intermittently sprays postmortem beef carcasses to reduce carcass temperatures, has occurred in the US since the late 1980s. Beef spray chilling consumes approximately 5% of the water needed to process a single head (Li et al., 2018). Many studies, occurring from the late 1980s to the late 1990s, have determined spray chilling is an economically advantageous process as it reduces postmortem carcass chilling losses, or shrink. Much of the moisture retained from spray chilling has been traced to the exterior of the carcass (Johnson et al., 1988); however, no knowledge exists on spray chilling’s impact on salable yield.

The objective of this study was to evaluate the impact of a more sustainable, reduced water use beef spray chilling on beef carcass chilling rate, quality, safety, and salable yield. These objectives were met by comparing a reduced volume to a conventional, high volume spray chilling protocol. These protocols were tested to determine the influence of water volumes on carcass chilling losses, chilling temperature declines, USDA grade, microbial reduction, tenderness, cutability, and composition.

Methodology

Carcass sides (N = 1,978 paired sides) were subject to alternative chilling treatments. Prior to chilling, all side weights were evaluated on the harvest floor, and a subset of paired sides (n = 72 paired sides) were subjected to microbial analysis (aerobic and coliform bacteria) at three locations (round, flank, and brisket). Additionally, paired sides selected for microbial analysis (n = 72 paired sides) were electronically monitored for temperature declines of the deep round, loin and carcass surface throughout the entirety of chilling. One side was conventionally spray chilled with 104.1 L over a 12 h period, while its pair was chilled with 3.2 L of water over a 3 h duration.

After chilling, chilled weights were obtained and paired sides were simultaneously evaluated for USDA grade attributes via instrumental analysis. Sides selected for microbial analysis were segregated to a single rail in the merchandizing cooler for post-chilling collection. Eighty-five carcasses (n = 85 paired sides) were selected at grading with a pre-determined selection matrix for a full carcass cutout.

Fabricated carcasses (n = 85 paired sides) were processed by highly skilled plant workers. Specifications for each subprimal were subject to the processing facility. Weights of all components (subprimals, trim, fat, and bone) were collected prior to and after primal fabrication. One striploin steak was collected from each side (n = 85 paired sides) for determination of 3 day shear force analysis (Warner-Bratzler and slice shear force). Additionally, nine whole muscle samples (n = 765 paired muscles), six trim samples (n = 510 paired trimmings), six general fat samples (n = 510 paired fat samples), and three external fat samples (n = 255 paired external fat samples) were collected from each paired side to represent chilling differences on proximate composition in each primal. Proximate analysis was determined with near infrared spectrometry (NIR), as well as oven drying moisture analysis.

Findings

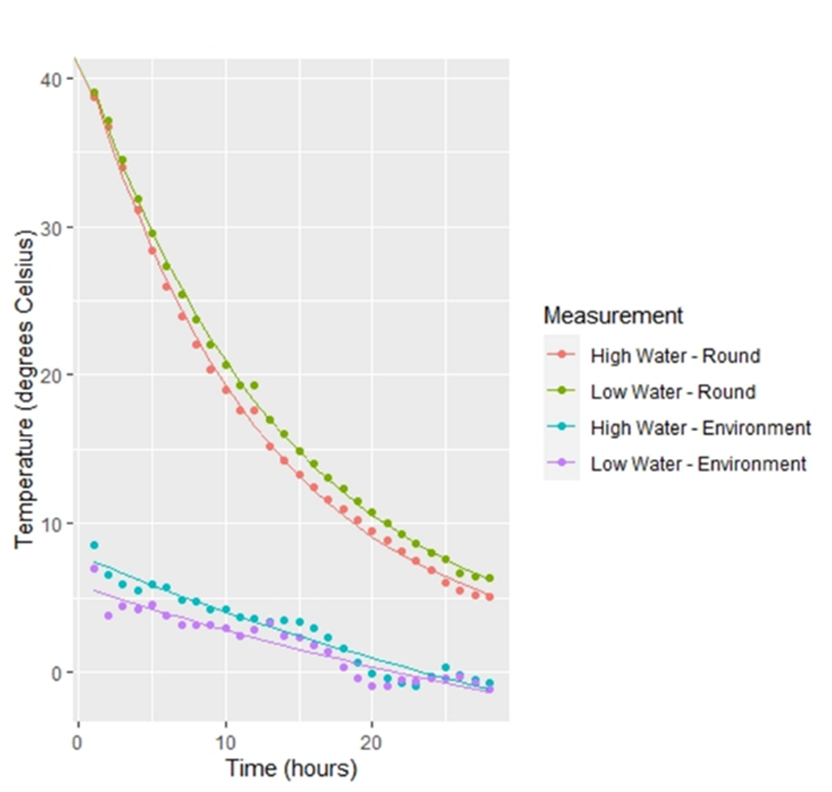

This study showed reduced water volumes applied during spray chilling resulted in increased carcass chilling losses and/or shrink. Water volumes applied during spray chilling did not affect microbial loads. Water volumes applied during spray chilling did not alter loin and surface temperatures; however, conventional spray chilling resulted rounds with 1.26 °C lower 28 h temperatures than paired reduced spray chilling rounds (5.09 vs 6.35°C, respectively). Lesser volumes of water applied during chilling resulted in lesser fat and adjusted fat thickness opposite the ribeye. This resulted in a 0.04 lower numerical yield grade. High water volumes during spray chilling resulted in a 4 degree increase in marbling score. Though these changes occurred, they were not large enough to alter USDA yield and quality grade distributions between chilling protocols. Total subprimal weight was not influenced (P = 0.34) by water volumes applied during spray chilling. High volume water usage during spray chilling resulted in increased weight of total fabricated side fat. This weight variation resulted in low water spray chilled sides being comprised of a greater percentage of subprimals (P < 0.001) and salable yield (P = 0.01) compared to traditionally chilled sides. These finding were validated by increased moisture percentages in all external fat trimmings of conventionally spray chilled sides, along with increased NIR moisture percentages in general fat trimmings from four out of the six tested primals from these sides. Finally, beef tenderness was not altered.

Implications

With water security concerns arising, processors must seek areas where they can reduce water consumption to increase sustainability and longevity of operations at their facility. Our findings indicate water volumes applied during spray chilling can be reduced without altering beef quality, safety, tenderness, or percent salable yield. Furthermore, decreased water volumes applied during spray chilling generate lesser quantities of total fat that must be rendered. This reduction would allow for lesser quantities of water and energy required for the rendering process.

Figure 1. Temperature declines of reduced, low water spray chilled rounds and conventional, high water spray chilled rounds, with respect to the environmental temperature of their hotboxes.

Table 1. The effect of water volumes applied during spray chilling on cutout side, quarter, primal, and portion yields of fabricated paired sides (n = 85 paired carcasses)1.

|

Fabricated Weight, kg2 |

Percent of Side, %2 |

|||||||

|

Item |

High Water |

Low Water |

SEM3 |

P-Value4 |

High Water |

Low Water |

SEM3 |

P-Value4 |

|

Fabricated Portion |

|

|

|

|

||||

|

Subprimals |

0.00 |

(0.36) |

2.54 |

0.34 |

0.00 |

0.33 |

0.35 |

< 0.001 |

|

Trim |

0.00 |

(0.38) |

0.64 |

0.03 |

0.00 |

(0.10) |

0.15 |

0.27 |

|

Fat |

0.00 |

(0.56) |

0.64 |

< 0.01 |

0.00 |

(0.19) |

0.19 |

0.02 |

|

Bone |

0.00 |

(0.32) |

1.42 |

0.06 |

0.00 |

(0.04) |

0.37 |

0.56 |

|

Backstrap |

0.00 |

(0.02) |

0.03 |

0.15 |

0.00 |

0.01 |

0.01 |

0.24 |

|

Total Salable Yield5 |

0.00 |

(0.74) |

1.42 |

0.08 |

0.00 |

0.23 |

0.09 |

0.01 |

-

1High Water = conventional spray chilling with 104.1 L/sided over 12 h; Low Water = reduced spray chilling with 3.1 L/side over 3 h.

2Fabricated Weight = High Water, kg - Low Water, kg; Percent of Side = % of High Water Side - % of Low Water;

3Pooled (largest) standard error of least square means.

4Observed significance level for main effect of water volumes applied during spray chilling.

5Total Salable Yield = subprimals and trim.

Table 2. The effect of water volumes applied during spray chilling on compositional percentage of moisture in fat collected from paired sides (n = 85 paired sides)1.

|

Item |

HW |

LW |

SEM2 |

P – Value3 |

|

External Fat4 |

|

|

|

|

|

Round |

22.68 |

21.56 |

0.44 |

0.04 |

|

Loin |

15.28 |

12.62 |

0.43 |

<0.001 |

|

Rib |

13.50 |

11.85 |

0.48 |

0.01 |

|

Fat4 |

|

|

|

|

|

Round |

32.32 |

27.59 |

0.77 |

<0.001 |

|

Loin |

19.90 |

17.92 |

0.76 |

<0.01 |

|

Flank |

18.35 |

17.31 |

0.67 |

0.22 |

|

Rib |

31.86 |

31.37 |

0.84 |

0.51 |

|

Navel and Brisket |

24.67 |

23.17 |

0.69 |

0.02 |

|

Chuck |

18.09 |

16.09 |

0.91 |

0.04 |

-

1High Water = conventional spray chilling with 104.1 L/sided over 12 h; Low Water = reduced spray chilling with 3.1 L/side over 3 h.

2Pooled (largest) standard error of least square means.

3Observed significance level for main effect of water volumes applied during spray chilling.

4External Fat = moisture percentage determined by oven drying; General Fat = moisture percentage determined by near infrared spectrometry

References

-

Rotz, C. A., S. Asem-Hiable, S. Place G. Thoma. 2019. Environmental footprints of beef cattle production in the United States. Agric. Syst. 169:1 – 13. doi: 10.1016/j.agsy.2018.11.005

- Asem-Hiablie, S., T. Battagliese, K. R. Stackhouse-Lawson, C. A. Rotz. 2019. A life cycle assessment of the environmental impacts of a beef system in the USA. Int. J. Life Cycle Ass. 24:441 – 455.

- Li. S, R. M. M. Ziara, B. Dvorak, J. Subbiah. 2018. Assessment of water and energy use at process level in the U.S. beef packing industry: Case study in a typical U.S. large-size plant. J. Food Process Eng. 41. doi:10.1111/jfpe.12919

- United States Department of Agriculture. 2017. United States standards for grades of beef. Agricultural Marketing Service. Livestock and Seed Division. Washington, D.C.

- Johnson, R. D., M. C. Hunt, D. M. Allen, C. L. Kastner, R. J. Danler, and C. C. Schrock. 1988. Moisture uptake during washing and spray chilling of Holstein and beef-type steer carcasses. J. Anim.Sci. 66: 2180 – 2184. doi.org/10.2527/jas1988.6692180x