Project Summary

Survey of pathogen Interventions and Best Practices Used by Beef Harvesters and Processors

- Principle Investigator(s):

- S. P. Langly, J. W. Savell, and K. B. Harris

- Institution(s):

- Texas A&M University

- Completion Date:

- May 2009

Background

Food safety has been a common goal of the meat industry for many years. By designing and implementing food safety systems to address specific pathogens of concerns, each establishment is ensuring that safe beef products are being produced for the consumer, which is the ultimate goal of the industry. With advancing technology, the beef industry has developed many different strategies to reduce or eliminate reasonably likely to occur hazards, including E. coli O157:H7. These strategies were termed interventions. Several advancements in interventions have been made; however, there is limited knowledge of how many plants use interventions, what types of interventions are used; or how many interventions are applied throughout the system. Each time there is a recall or a food safety outbreak, industry practices are questioned and often criticized by both the Food Safety and Inspection Service (FSIS) and consumers. Due to recent recalls and outbreaks related to E. coli O157:H7, industry practices are under scrutiny. In order to better defend industry practice and/or to address areas that need improvement, the industry must first determine exactly what interventions and food safety practices are being applied across all industry sectors.

The stated objectives for this work were to survey establishments that harvest beef, produce non-intact beef products and produce ground beef to determine the types of pathogen intervention(s) being applied, methods used to validate these interventions(s), frequency of validation, types and frequency of pathogen testing conducted, sampling procedures and protocols for pathogen testing, use and knowledge of Industry Best Practices, as well as to identify key food safety needs or issues.

Methodology

A seven-page survey was developed, of which there were specific sections designed for each of the types of processes (slaughter, fabrication, intact raw beef products, non-intact raw beef products, and raw ground beef) surveyed. The survey was provided in a written format and as an online survey. The survey was designed to obtain information from an establishment about the types and frequency of pathogen testing conducted, types of pathogen intervention(s) being applied, methods used to validate these intervention(s), frequency of validation, sampling procedures and protocols for pathogen testing, and the use of Industry Best Practices. Demographic information was collected on the FSIS size classification of the establishment and the number of employees of that establishment. Participants for the survey were select by using the FSIS Meat, Poultry and Egg Product Inspection Directory. Upon return of the surveys, telephone interviews were conducted to clarify answers and or to obtain additional information needed. The follow-up questions were specific for the process and based on the responses obtained from the survey. Selected establishments that completed the surveys from each sector (harvest, non-intact processing, and grinding) were visited to verify information collected from the survey was actually being applied in the plant, and that the data support the validation of the interventions. Establishments were selected to represent different locations and sizes of operations.

Findings

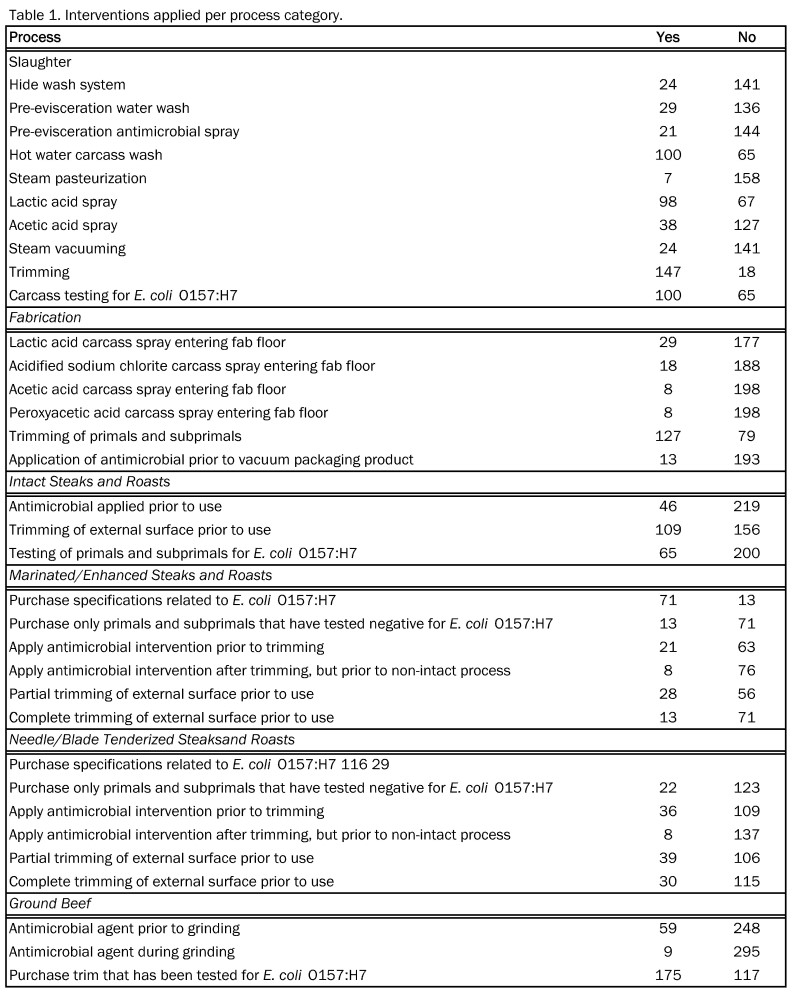

A total of 5,667 surveys were disseminated to federally inspected establishments, and 1,161 surveys were completed and returned. Of the completed surveys, 40% were beef operations. Results of the survey show that a variety of interventions are being applied throughout the different processes, and that some interventions have been validated using in-plant testing while others have no validation data (Table 1). The written survey results show that many establishments were familiar with the Industry Best Practices; however, establishments seemed less familiar with the Best Practices for Vacuum-packaged Subprimals and the Best Practices for Pathogen Control During Tenderizing/Enhancing of Whole Muscle Cuts than with the others. The results show that each processing category has developed and implemented food safety systems; however, there is still a need for improvements in some areas.

Implications

The results of the survey can be used to support actions being taken in establishments that slaughter, fabricate, intact steak and roast, marinated/enhanced products, needle/blade tenderized products, and ground beef. Therefore, these results should have a positive impact on the industry. Also, the results identify areas where additional information can be developed, and educational activities can be utilized to strengthen existing food safety programs. Overall, the results provide a much better understanding of the current beef safety programs being utilized throughout the industry.