Project Summary

Applications of Novel Yam Starch Films Containing Antimicrobial Agents to Improve Beef Safety

- Principle Investigator(s):

- Mengshi Lin, Ruoyu Li, Fangbai Sun, Charis Chiu, and Azlin Mustapha

- Institution(s):

- University of Missouri

- Completion Date:

- 2010

Background

E. coli O157:H7 is one of the most important foodborne pathogens in the beef industry and has resulted in a number of highly publicized and expensive recalls. Traditional antimicrobial agents widely used in the beef processing plants include quaternary ammonium compound, chlorine, acetic acid, and others. Many of these acidic and alkaline sanitizers are corrosive, emit unpleasant odors, discolor surfaces, and are often vulnerable to harsh processing conditions and abusive factors during transport and storage (high temperature, high pressure, humidity), resulting in the loss of their antimicrobial properties due to decomposition or sublimation of the antimicrobial agents.

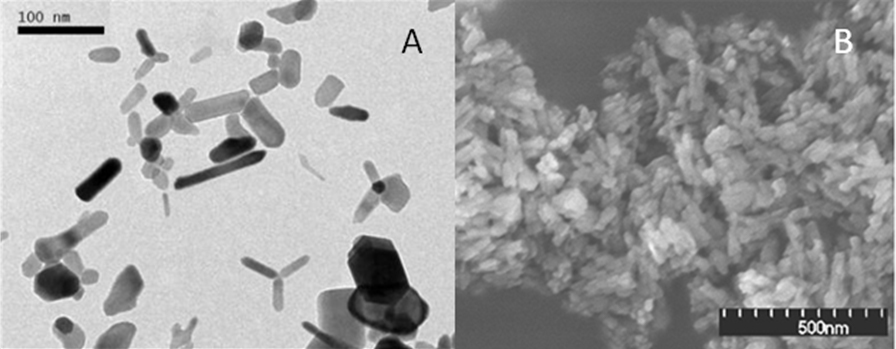

Novel inorganic antibacterial materials such as metal or metal oxides nanoparticles (NPs) have received increasing attention in recent years because they are non-corrosive, odorless, and stable under harsh processing conditions. Particularly, inorganic NPs made from metal oxides with sizes less than 100 nm exhibit antimicrobial activities due to their special characteristics such as small particle size and large surface area.

With recent advances in film production and technology, there is growing interest in the applications of novel antimicrobial films and coatings in microbial food safety. Yam (Dioscorea alata) starch can form a transparent, colorless, odorless, and flexible film which is an excellent oxygen and moisture barrier as a packaging material for food products.

The objectives of this study were to evaluate antimicrobial properties of novel inorganic antimicrobial agents (zinc oxide nanoparticles (ZnO NPs) and calcium phosphate hydroxyapatite (CaHA NPs) against an important foodborne pathogen, E. coli O157:H7; study the mode of action of NPs against bacteria and the development of bacterial biofilms on stainless steel; and develop and use yam starch films containing antimicrobial NPs to inhibit the growth of E. coli O157:H7 in beef products.

Methodology

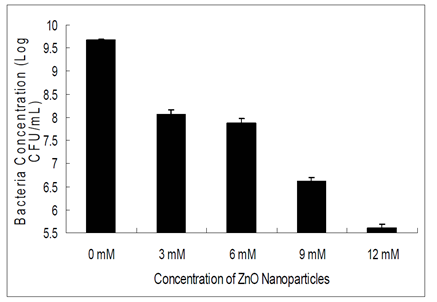

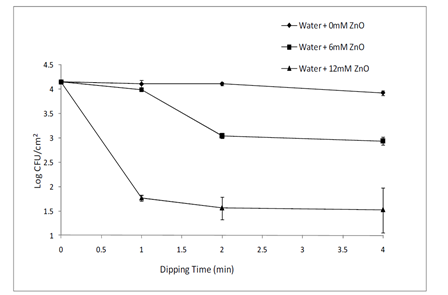

E. coli O157:H7 were obtained from the culture collection in the Food Microbiology laboratory at the University of Missouri, Columbia, MO. ZnO NP suspensions with NP size of ~70 nm were purchased from a commercial source. CaHA NPs with NP size of ~50 nm were synthesized with a solution method. Antibacterial tests were performed by inoculating bacterial cells on TSA plates containing different concentrations of ZnO NPs (0, 3, 6, 9, and 12 mM) and CaHA NPs (0, 5, and 20 mM). Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) were used to examine morphological changes of E. coli O157:H7 cells before and after treatment with NPs. Stainless steel coupons (type 304, 2×2 cm) were used in antimicrobial analysis of using NPs to inhibit the development of bacterial biofilms. Coupons were dipped in NP suspensions (0, 6, and 12 mM) for 0, 1, 2, and 4 min and the bacterial counts of survival E. coli O157:H7 cells were obtained by plating samples. Yam starch films were prepared, and glycerol was used as a plasticizer. Various concentrations of ZnO NPs were incorporated into yam starch films. Films were used for antimicrobial tests on sirloin beef cuts.

Findings

The effects of ZnO NP on the formation of E. coli O157:H7 biofilms on the surface of stainless-steel coupons were evaluated. The studies were conducted at 4°C and 21°C for 5 h and 24 h incubation time. Results demonstrate that when dipping time of coupons in ZnO NP suspensions increased, the antibacterial effects became more significant. The 12 mM ZnO suspension was proven to be more effective than the 6 mM ZnO suspension (Figure 2). These results demonstrate that ZnO NPs were effective in inhibiting the development of E. coli O157:H7 biofilms on the surface of stainless steel. Yam starch films containing ZnO NPs were prepared and used in antimicrobial analysis for E. coli O157:H7 in sirloin beef cuts at 4°C. After 6 days, the inhibitory effect of yam starch films with 6 mM and 12 mM ZnO NPs became significant, resulting in less bacterial growth than other samples (treatments of no film attached or yam starch film containing no ZnO NPs) (Figure 3). In summary, ZnO NPs were found to have a stronger antibacterial activity against E. coli O157:H7 than CaHA NPs. The inhibitory effects increase as the concentration of ZnO NPs increases. ZnO NPs could be used to inhibit the development of E. coli O157:H7 biofilm on the surface of stainless steel and incorporated into yam starch films to control the growth of E. coli O157:H7 on beef cuts.

IMPLICATIONS

These results suggest that ZnO NPs could be used as an effective antibacterial agent to protect the safety of beef products. Yam starch has long been used as a traditional medicine that provides great health benefits, while ZnO have excellent biocompatibility and bioactivity and are stable under harsh processing conditions. Together, they could provide novel intervention strategies for pathogen control in the beef industry. Beneficiaries of this research would be beef processors who would have practical control treatments and novel antimicrobial agents to use in processing of beef products. The results obtained under this project would help U.S. beef products to become more competitive in domestic and foreign markets by providing an assurance of product safety.

Figure 1. TEM image of zinc oxide nanoparticle suspension (A) and SEM image of calcium phosphate hydroxyapatite nanoparticles (B).

Figure 2. Antibacterial effects of ZnO Np on E. coli O157:H7 in TSA in the presence of different concentrations of ZnO NPs.

Figure 3. Antimicrobial effects of ZnO NPs on E. coli O157:H7 biofilm on stainless steel at 21°C for 24 h incubation time.