Project Summary

Effect of Meat Packaging Technologies on the Safety and Spoilage-Indicating Characteristics of Ground Beef – Phase I: Safety Characteristics

- Principle Investigator(s):

- Mindy M. Brashears, J. Chance Brooks, and Mark F. Miller

- Institution(s):

- Texas Tech University

- Completion Date:

- May 2006

Background

Recent petitions to FDA and USDA have requested the re-evaluation of carbon monoxide gas as an approved packaging component. The Food and Drug Administration (FDA) and USDA FSIS requires that approved processes and/or ingredients do not in any way result in the product becoming adulterated or misbranded including the presence of microbial pathogens. Thus, research was needed to provide the industry and government officials with scientific data regarding the safety characteristics of various packaging systems commonly used in the beef industry.

The stated objective for this work was to determine the safety of ground beef packaged with carbon monoxide gas flush, hi-oxygen gas flush, and rosemary oleoresin in modified atmosphere packaging of ground beef patties by determining the growth or survival of E. coli O157:H7 and Salmonella over time.

Methodology

Experimental Design

The survival of E. coli O157 and Salmonella was evaluated in ground beef patties exposed to five treatments as follows: 1) control (foam tray with film over-wrap); 2) high-oxygen (80% O2 / 20% CO2) modified atmosphere package (MAP); 3) high-oxygen MAP with added rosemary extract; 4) low-oxygen carbon monoxide (0.4% CO, 30% CO2, 69.6% N2) MAP; and 5) low-oxygen carbon monoxide MAP with added rosemary extract.

The project was a split-plot design with meat block serving as the main plot and blocked by a retail display case. Data was analyzed using the GLM procedures of SAS. Least-square means were computed for each dependent variable, and statistically separated by pair-wise t-test (PDIFF option of SAS) with predetermined α = 0.05. MAP samples could not be unpackaged and used for repeated measures, so samples were replicated over time.

Preparation of Patties

Coarse ground beef was obtained from a commercial processor immediately after its release from the company’s “test and hold” program and transported to the Texas Tech University BSL II Pathogen Processing Laboratory for processing. The coarse ground beef was placed in a mixer and blended prior to a final grind. After the final grind, patties were formed (150 g) using a hand operated patty maker. All equipment was cleaned, rinsed and dried between each treatment. Rosemary extract was added to the coarse ground beef and mixed prior to a final grind. Additionally, concentrated cultures of a 3 strains mixture of Salmonella and a 4 strain cocktail of E. coli O157:H7 were added during grinding to yield populations of approximately 1 x 104 CFU/g. Beef patties were evaluated for changes in microbial loads over time (0, 1, 3, 5, 7, 14 and 21 d) under simulated retail display conditions using coffin-style and multi-deck cases under continuous fluorescent lighting (approximately 1900 lux using high-output bulbs with a color temperature rating of 3500°K).

Microbiological Tests

On each day of sampling, packages were aseptically opened and subjected to serial dilutions in peptone dilution water. Samples inoculated with Salmonella were plated on XLD agar overlayed with TSA using the thin-layer agar method to allow for recovery of injured cells. Samples containing 3

E. coli O157:H7 were plated onto MacConkey Agar overlayed with TSA using the thin-layer agar method as well. Samples were plated using a spiral plating system and counted using a Q count automated counting system. All plates were incubated for 24-28 h at 37oC prior to counting.

Findings

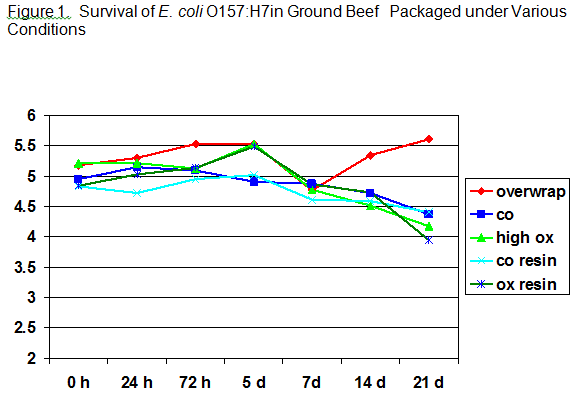

Figure 1 illustrates the changes in the populations of E. coli O157:H7 over time in ground beef during storage in various packaging materials at refrigeration temperatures. On day 1, there were no significant differences in the populations of the pathogens in all packages with total initial counts of E. coli O157:H7 ranging from 4.83 to 5.20 log10 CFU/g. On days 1, 3, 5, and 7, there were no significant increases or decreases in the populations and no differences among counts of E. coli O157:H7 in the various packages.

Significant differences were observed on day 7. In the MAP packages, E. coli O157:H7 populations ranged from 4.51 - 4.73 log10 CFU/g with no differences among the counts of E. coli in the ground beef in the various packages. The total E. coli O157:H7 in the ground beef in the traditional overwrap packages was at 5.73 log10 CFU/g which was significantly higher than the counts in the ground beef in the MAP packages. After 21 days, the total counts of E. coli O157:H7 in ground beef packaged in traditional packaging increased to 5.60 log10 CFU/g and this was significantly higher than all E. coli O157:H7 counts in the ground beef in the MAP packages. The E. coli O157:H7 counts in the MAP packages on day 21 ranged from 3.94 to 4.34 log10 CFU/g.

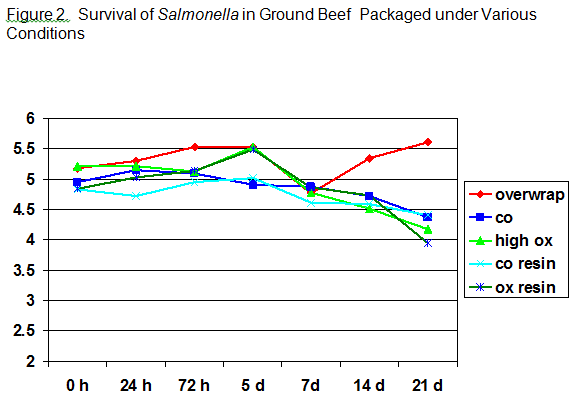

Similar results were observed for samples inoculated with Salmonella. On day 7, the initial populations ranged from 4.40 to 4.58 log10 CFU/g (Figure 2). There were significant differences observed among the treatments after 3 days of storage. Samples packed in traditional packaging had total Salmonella counts of 5.20 log10 CFU/g while all those in MAP packages were significantly lower at 4.50 log10 CFU/g. Similar results were observed on day 5, but after 7 days there were no significant differences among the treatments. After days 14 and 21, the total Salmonella in the ground beef subjected to traditional overwrap packaging was at 4.29 and 4.27 log10 CFU/g, respectively which was significantly higher than counts in the MAP packages which were between 4.30 and 3.94 log10 CFU/g on day 14 and between 3.75 and 4.01 log10 CFU/g on day 21.

Over time the reductions in E. coli O157:H7 and Salmonella could be occurring due to the presence of carbon dioxide in the atmospheres. It has been known for some time that carbon monoxide is inhibitory towards various microorganisms. Further research is needed to determine the inhibitory factors in the packaging gases.

Implications

For product packaged in modified atmospheres (high-oxygen (80% O2 / 20% CO2)) and low-oxygen carbon monoxide (0.4% CO, 30% CO2, 69.6% N2) both with and without rosemary oleoresin) the total numbers of Salmonella and E. coli O157:H7 decreased over time. Modified atmospheres may be inhibitory to foodborne pathogens and may provide added safety to ground beef products.